An Exclusive Inside Look at Sennheiser's Headquarters in Germany

Posted on: 30th January 2025

An Exclusive Inside Look at Sennheiser’s Headquarters in Germany

On Tuesday 21st January we flew 3 lucky customers out to Sennheiser’s headquarters in Germany, for their competitive prize that celebrates the transition from Evolution Wireless Analogue to Evolution Wireless Digital and EW-DX.

Join us as we take you on a behind the scenes tour of Sennheiser’s headquarters, with our customers OneBigStar, Extreme Productions and PCL Live.

A Historic Welcome

The journey began as we pulled up to the Sennheiser building. Standing on the very ground where Fitz Sennheiser first laid the foundations for the future of audio 79 years ago left us in awe. Looking up at the iconic Sennheiser logo proudly displayed over the courtyard, you couldn’t help but feel the weight of history.

The Original Farmhouse

Our excitement only grew as we made our way to the original farmhouse where the first Sennheiser microphone was created. In 1945, Fitz Sennheiser transformed this abandoned farmhouse into a space to innovate, and it’s here that we were shown the first ever prototype of the legendary MD421 Kompakt microphone.

What struck us most was the original shell, still marked by a hole from early tests where Sennheiser engineers tested how hard they could smash the microphone with a drumstick. This test ultimately led to improvements that shaped the design we know today. To hold such a historic artifact, especially in the very building where Sennheiser began, was nothing short of surreal.

A Tour of Innovation

Next, we ventured into the heart of Sennheiser’s operations: the offices and labs where the magic happens. These rooms were filled with desks and every piece of equipment you could – or couldn’t - even imagine, all working together to create the next-generation of audio products. It was overwhelming at times, but the sense of awe never faded. Here, highly skilled teams work tirelessly to advance the science behind the audio equipment we use every day.

Unfortunately, we couldn’t take photos or discuss specifics, but we’ll share one of the most memorable experiences: the Anechoic Chamber.

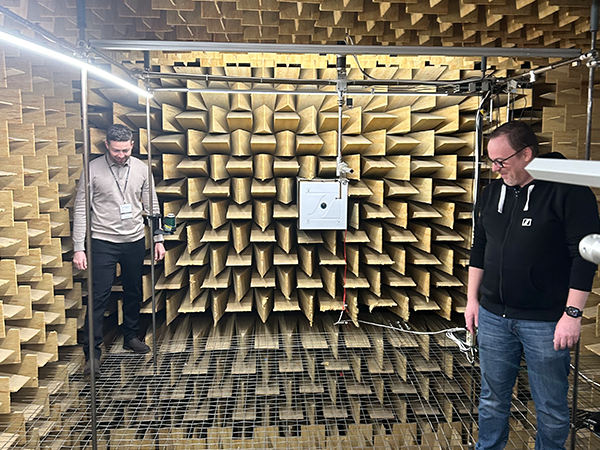

The Anechoic Chamber Experience

Standing in an anechoic chamber is like stepping into a world of complete silence. When Glenn (Leisuretec’s Technical Manager) and I stood in opposite corners, facing the walls, and spoke to each other, it felt like “having someone in your pocket” – as Glenn put it. The sensation of hearing only your voice with zero external refurb is truly surreal. And as an added bonus, we even passed Daniel Sennheiser in the hall on our way there – a moment I won’t soon forget!

All Things Technical

Next up, we met Marcus Blight, Sennheiser’s Technical Application Engineer working on their newest innovation in wireless audio: the Spectera WMAS wideband bidirectional digital wireless ecosystem. Marcus is easily one of the smartest people I’ve ever met! We dove into a first-hand look at the Spectera range in a fully-equipped meeting room, where we were encouraged to ask as many questions as possible.

One topic that stood out was Soundbase – a free program I’d never heard of before, but now highly recommend, especially for sound engineers. Soundbase allows you to plan and communicate your audio projects in a shared space, making it ideal for event organisers in new cities or areas with multiple engineers. This tool can make a significant difference in coordinating sound across various venues – I’ll link it below if you want to learn more about it.

After our session, we headed to the staff canteen for a spot of lunch, where we enjoyed a delicious traditional currywurst and chips, amongst the Sennheiser factory workers. This kept us fuelled and ready for one of the most exciting parts of our visit: the Sennheiser Factory Tour.

Behind the Scenes at the Factory

At the factory, we were shown the capsule room, where 3,000 microphone capsules are produced daily. Here, we learned that for every microphone made, 50,000 spools of copper are wound around a form. These copper springs float between the magnets in the microphone, and even the slightest overlap will render the microphone unusable. It’s astonishing to think of the level of precision required to produce each unit!

We also toured the Clean Rooms, where the back plates and diaphragms of microphones are assembled. These rooms had to be sterile as the space between both parts is only a quarter of a human hair thick! Even the smallest speck of dust could compromise the quality of the microphones, which is why the air in these rooms is replaced every 15 minutes! Looking into the rooms were specialists with their microscopes, all in hairnets, lab coats, gloves…the whole works!

It’s a true testament to the craftsmanship and attention to detail that goes into each Sennheiser product.

Wrapping Up the Day

Our visit ended back at the farmhouse, where we gathered for a recap of the day with our amazing guide, John McGregor, Sennheiser’s Sound Academy Manager. He gave us a sneak peek into Sennheiser’s exciting future projects, though we’ll have to leave those details under wraps for now.

Let’s just say - big things are coming!

Thanks for Joining Us!

hope you enjoyed reading about our incredible experience at Sennheiser’s HQ as much as I did experiencing it! It was a pleasure to experience firsthand the immense precision that goes into their iconic audio products, and really exciting to learn about their future innovations too. If you ever get the chance to visit, I’d highly recommend it!

If you’re interested in Sennheiser equipment or want more information about an upcoming project, don’t hesitate to reach out to us!